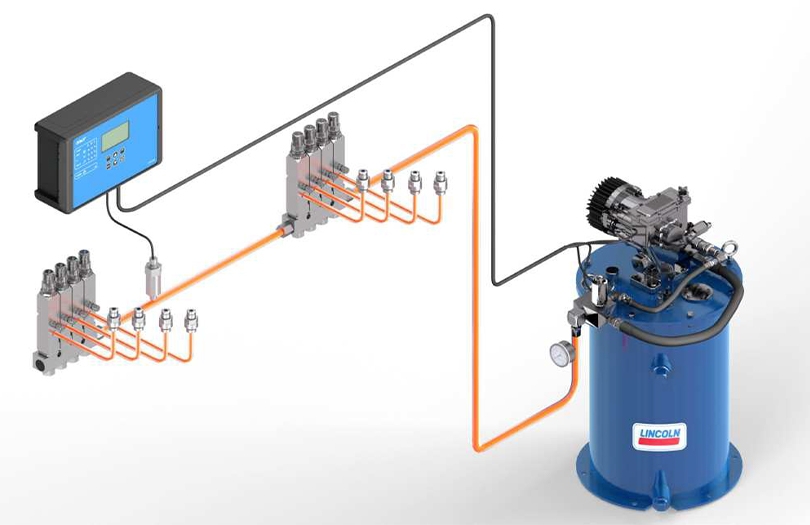

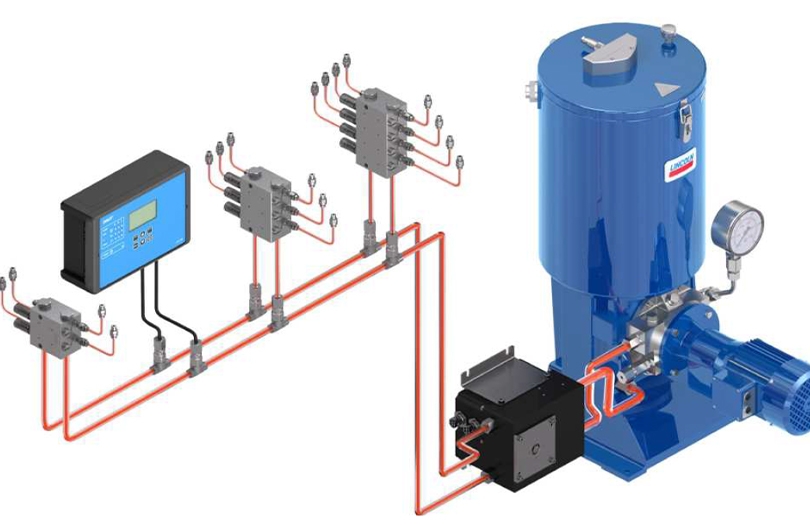

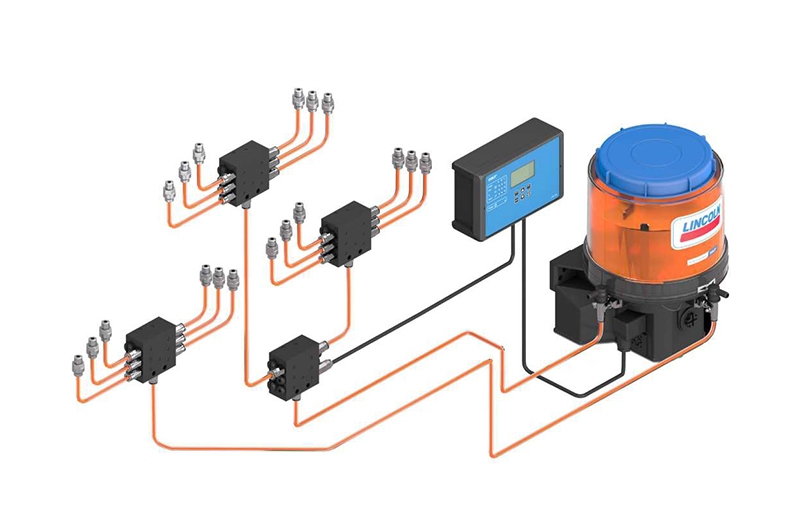

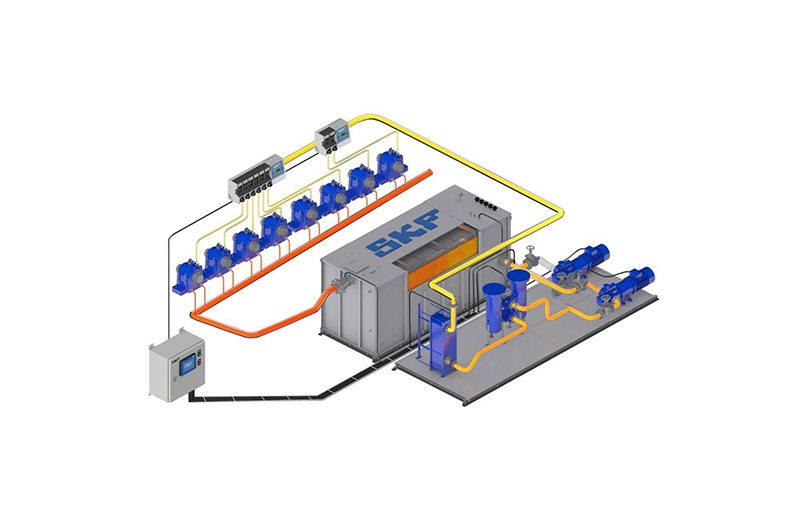

Automatic Central Lubrication Systems

Automatic central lubrication systems extend the life of equipment, save labor and time.

As Gresan, we support companies from many different sectors in lubrication systems with our expertise in lubrication systems and the quality of SKF-Lincoln brand, of which we are the distributor..

Lubrication is an important factor in the life and durability of machines. You can choose automatic central lubrication systems as an easy, fast, and error-free way to lubricate your machines without the cost and labor of lubrication.

Central lubrication systems are an effective way to increase machine efficiency by reducing human dependence. These systems minimize friction and wear by providing appropriate lubrication at the right intervals, optimizing the service life of both bearings and machines.

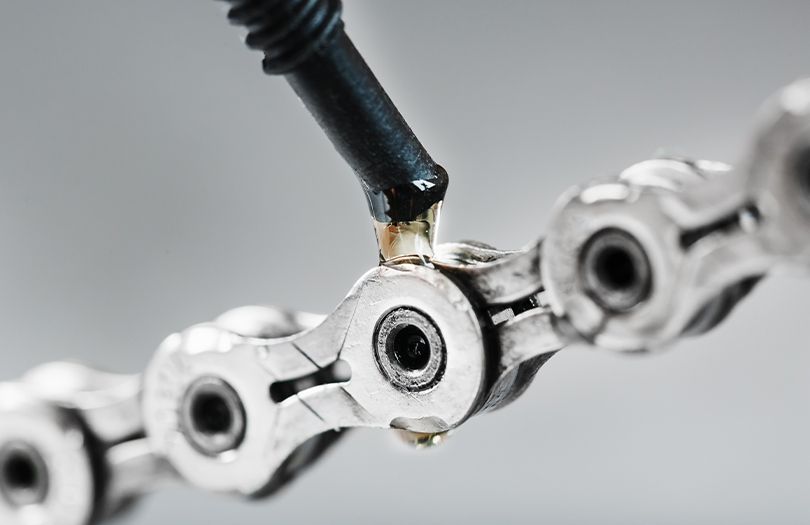

Although operators are aware of its impact on machine life, manual lubrication is susceptible to human error. During manual lubrication, incorrect dosages may occur. However, automatic lubrication systems designed to lubricate individual machines or entire facilities provide appropriate and precise lubricant supplementation to all necessary points.

In addition, with automatic centralized lubrication systems, there is no need to stop the machine for lubrication. The system continuously lubricates while the machine is running, requiring only that the lubrication system be kept filled and maintained.

Lubricating machines without stopping increases production efficiency. Lubricating while bearings are rotating also improves lubricant distribution. A small amount of grease continues to flow, preventing contamination even when the machine is operating in a harsh environment, extending the life of spare parts, and reducing repair and spare part costs.

Although the cost of installing an automatic lubrication system may be high initially, it will quickly pay off with the reduction in labor costs and advantages in using the correct lubricant dosage, as well as the impact it will have on machine life. It will provide long-term savings in your business.

In order to plan a lubrication system, the conditions in which the system will be used must be known in advance. The number of lubrication points, counter pressures at lubrication points, temperature range, and drive energy of the lubrication feed pump must be properly identified. After all these definitions, the selection and design of the lubrication system specific to your company's needs is done by the Gresan expert engineering team.

Benefits of Automatic Lubrication System:

- Significant savings in repair and replacement costs

- Increased machine life-time

- Up to 50% savings in lubricant costs due to accurate timing and dosing of lubricants

- Reduced downtime and production losses

- Reduced environmental impact

- Increased work and worker safety