Progressive

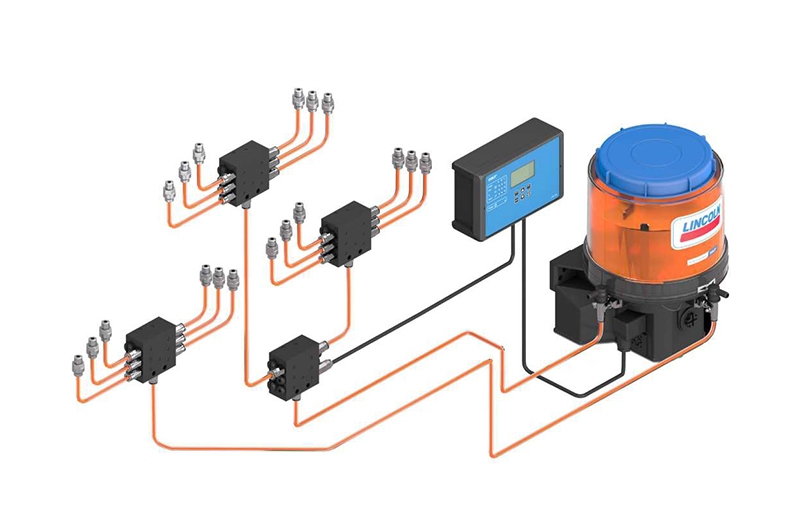

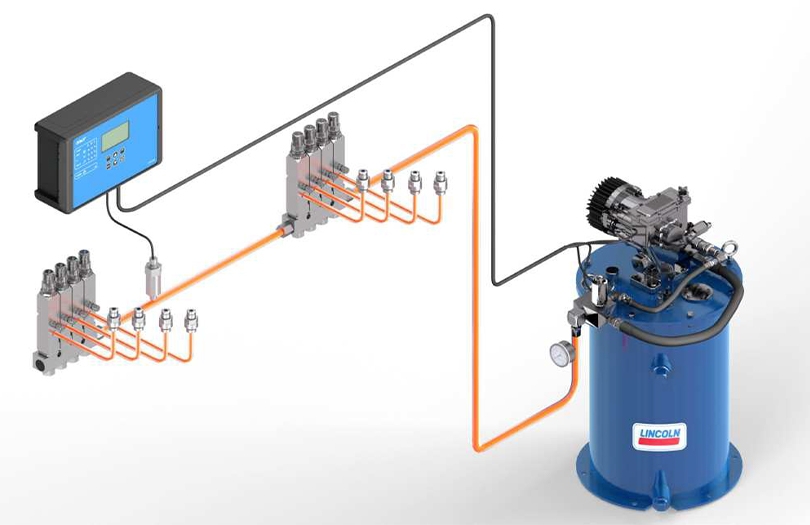

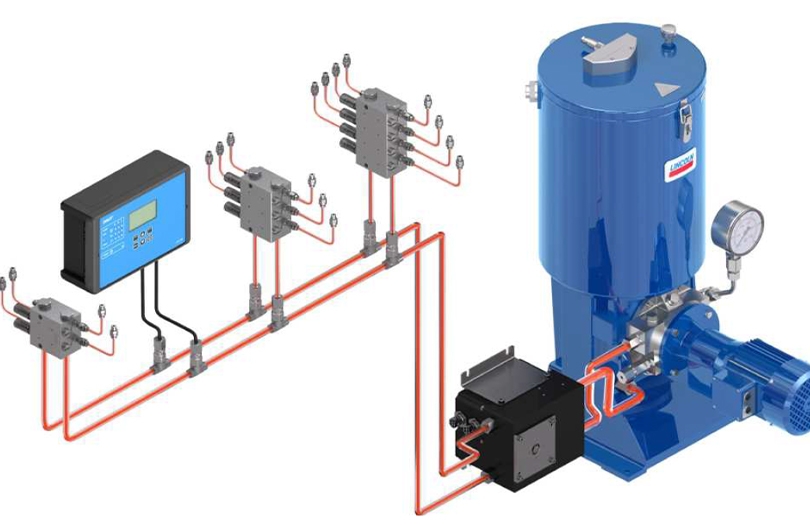

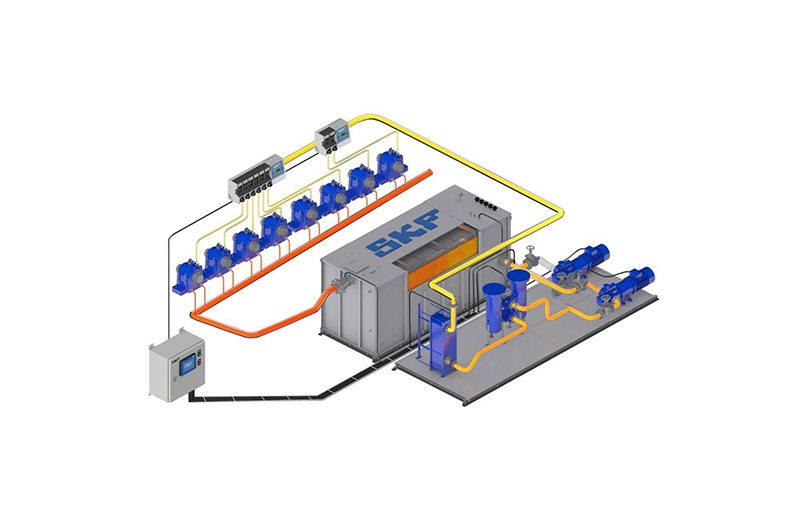

Progressive Lubrication System

For small to medium-sized machines that require continuous lubrication

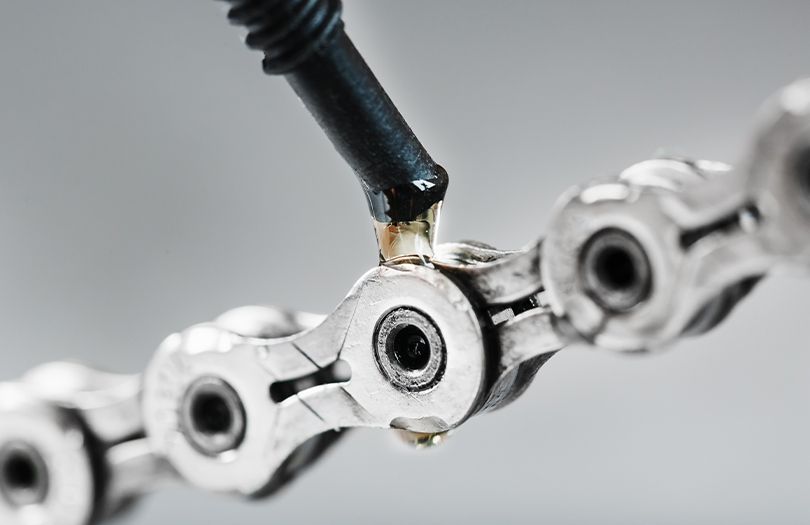

Progressive systems provide continuous lubrication as long as the pump is running. When the pump stops, the pistons of the progressive metering device also stops in their current positions. When the pump starts to supply oil again, the pistons can continue from where they left off. Therefore, oil transfer at only one output of the pump will stop when only one lubrication point is blocked. The blockage acts like a control tool and ensures early detection and intervention of a malfunction in the system.

Benefits of Progressive Automatic Central Lubrication System;

- Continuous lubrication

- Reliable monitoring and control

- Operation in harsh conditions

Some sectors where progressive lubrication systems are used;

- Construction machinery (concrete pumps, mortar pumps, loaders, excavators, trenchers) • On-road trucks (snow removal, waste compactor)

- Agricultural machines (combine harvesters, balers, fertilizer spreaders, sugar cane loaders)

- Wood reclaimers

- Material handling (access stackers, crane trolleys)

- Asphalt mixing plants

- Wind turbine generators

- Food and beverage facilities (fillers, washing machines)

- Oil and gas industry reciprocating compressors