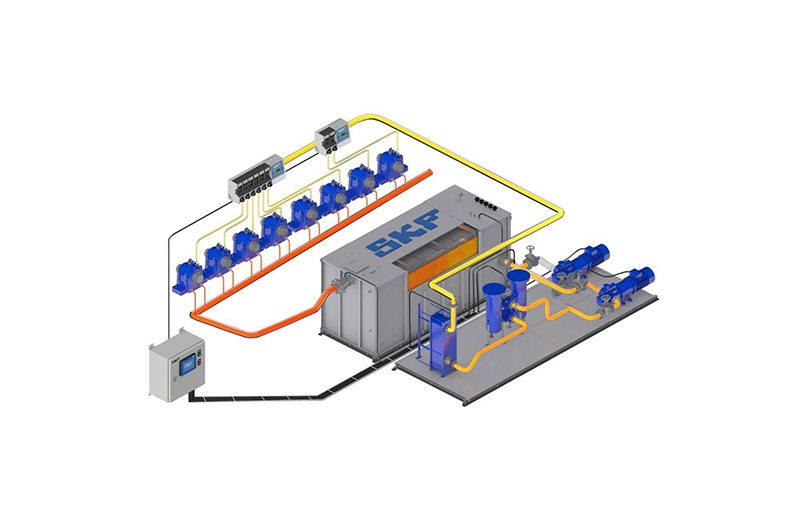

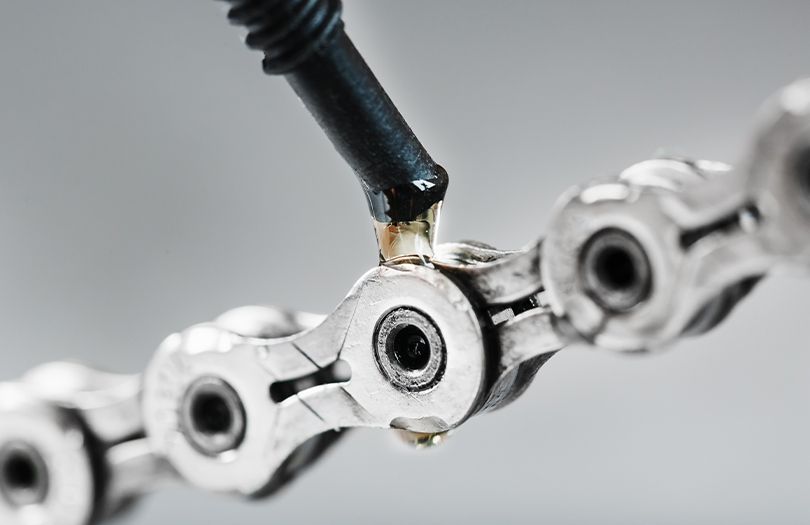

Circulation Lubrication

Circulation lubrication systems capture foreign particles at friction points, cleaning bearings and gearboxes during 24/7 cooling operations, and provide conditioned clean oil to bearings and gearboxes.

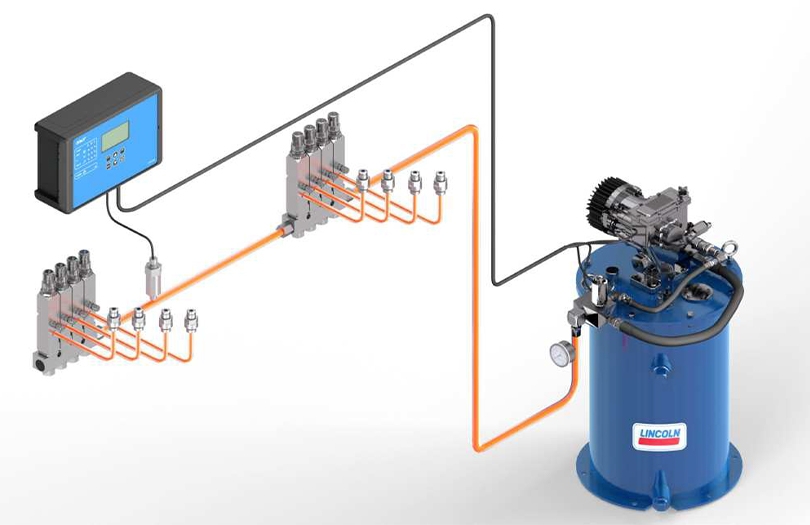

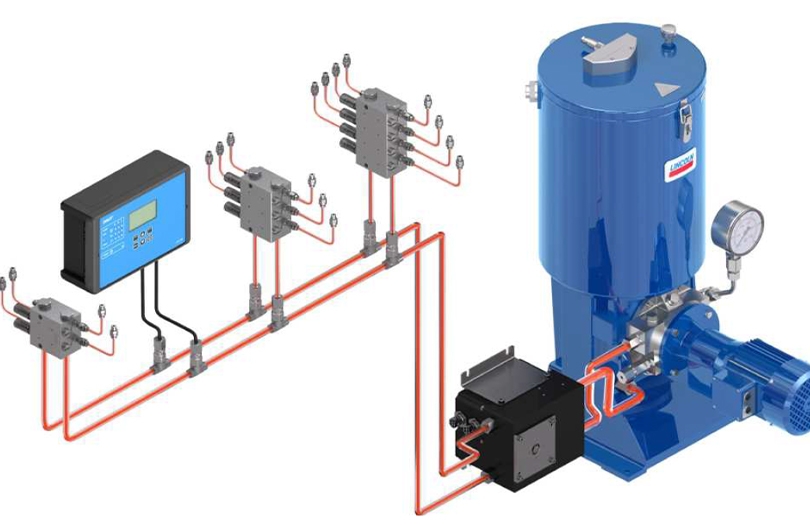

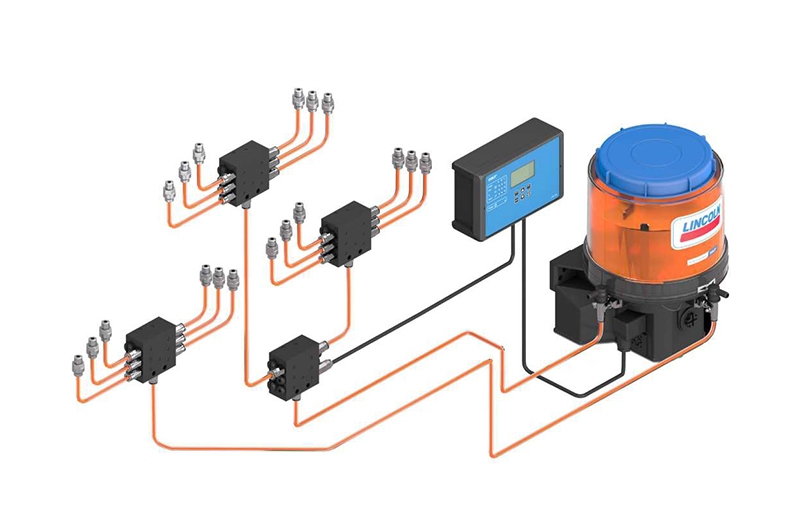

Customized turnkey solutions can be offered with circulation lubrication systems that provide accurate and reliable oil flow to each lubrication point. Using highly efficient oil with low rates on correct temperature and viscosity, high-capacity pump reservoirs increase machine usability and save energy.

A wide variety of flow meters enable purpose-built solutions and allow for monitoring and digitizing of lubrication flow using the latest technology.

Additionally, the maintenance processes of the system are easy, and lubrication points can be added to the system thanks to its expandable modular design.

Benefits of Circulation Lubrication Systems;

- Cooling of bearings and gearboxes • Removal of particles from bearings and gearboxes • High operational efficiency • Easy expansion of the lubrication system • Oil tank sizes range from 3 to 40,000 liters

Circulation lubrication systems are widely used in the following sectors:

- Iron and steel

- Cement

- Paper and printing

- Mining

- Refinery and Thermal Power Plants

- Food and Beverage •

Explosive environments (ATEX / EEX) (upon request)

- API (upon request)