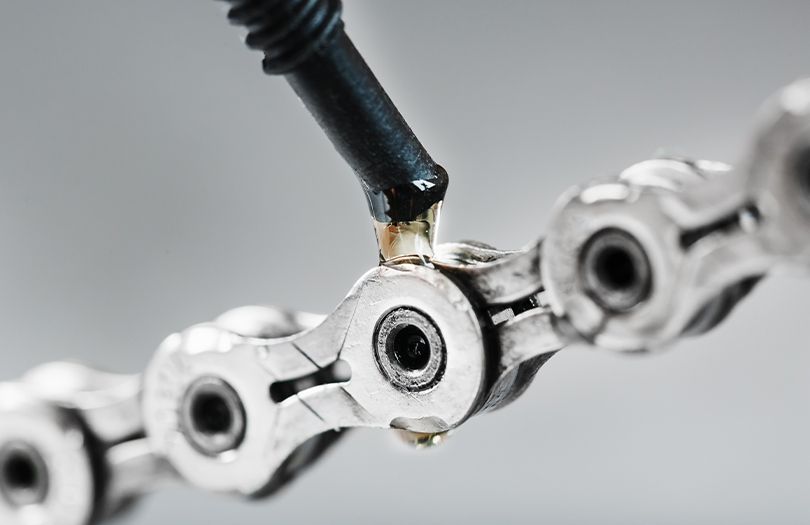

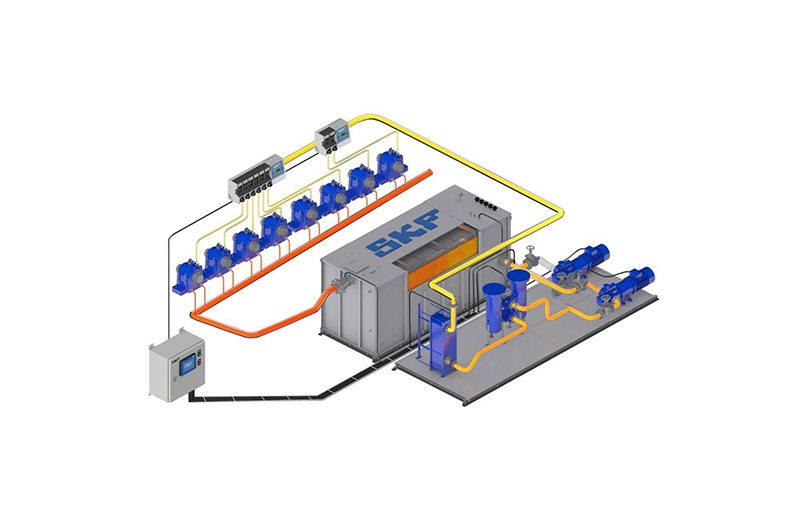

Chain Lubrication

Effective lubrication is key to maximizing the chain life. With proper lubrication, chain and conveyor equipment can be kept in motion. Chain lubrication systems can be designed to meet the needs of any chain type or lubrication requirements to prevent premature wear, corrosion, noise, and chain failure. Suitable lubrication is essential for maximum chain life. With proper lubricant selection, noise levels and energy consumption can be reduced. Inadequate lubrication can shorten chain life, causing excessive wear, elongation, noise, and vibration.

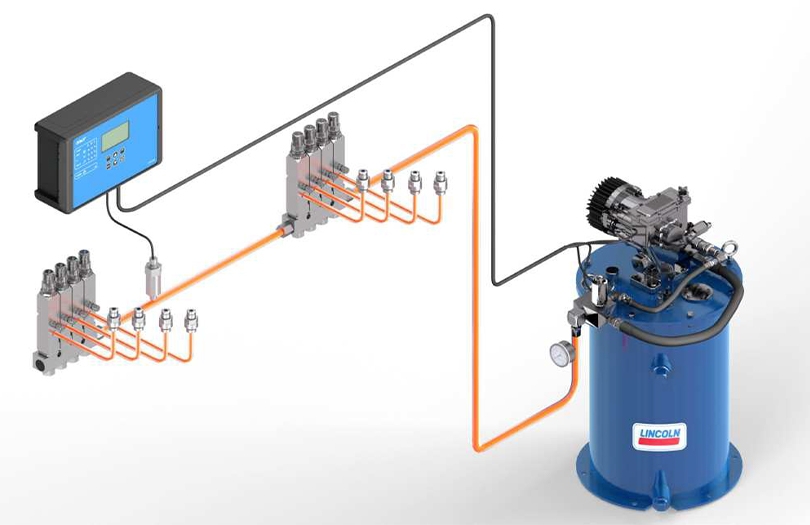

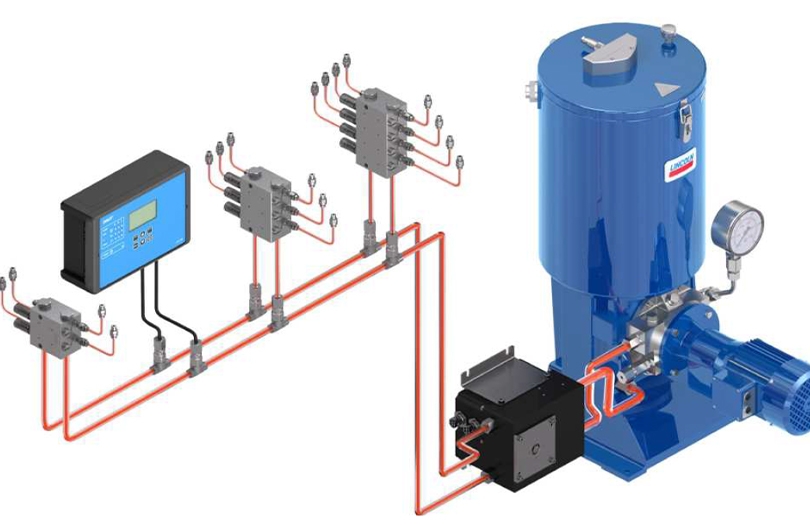

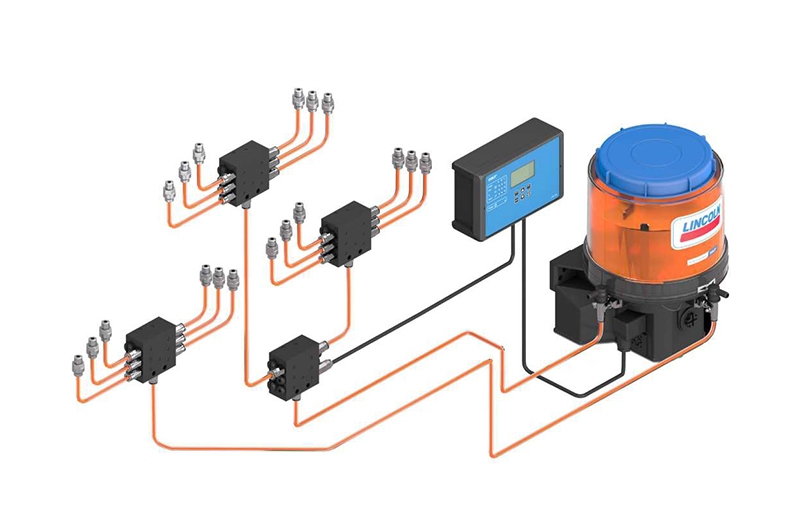

- With Chain Lubrication System;

- Maximize chain service life

- Minimize downtime due to insufficient lubrication

- Optimize lubricant consumption Increase worker safety

- Reduce labor time compared to manual lubrication

- Reduce energy consumption

- Deliver small and precise amounts of lubricant at the correct application point without waste at short intervals.

Chain lubrication systems are commonly used in areas such as conveyors, food and beverage ovens and processes, and general industry ovens.