Single-line

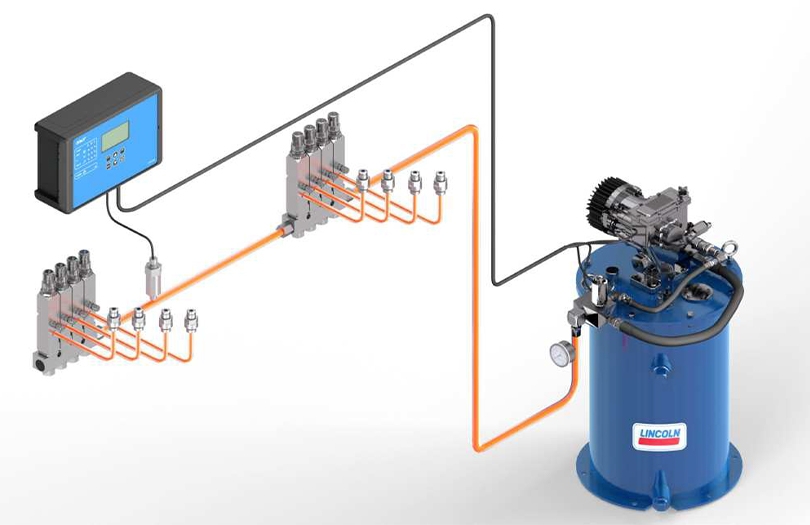

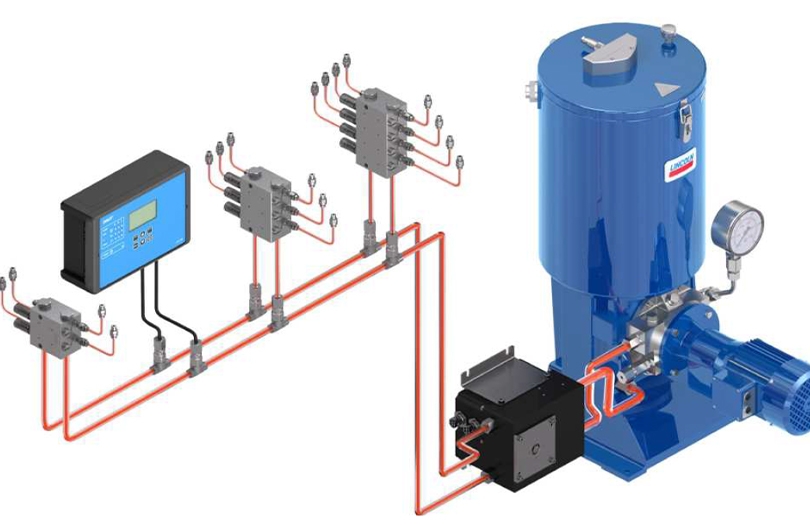

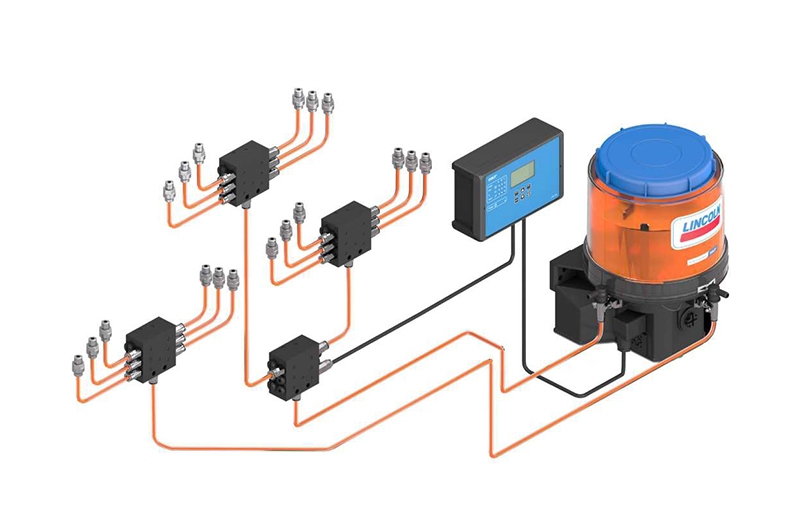

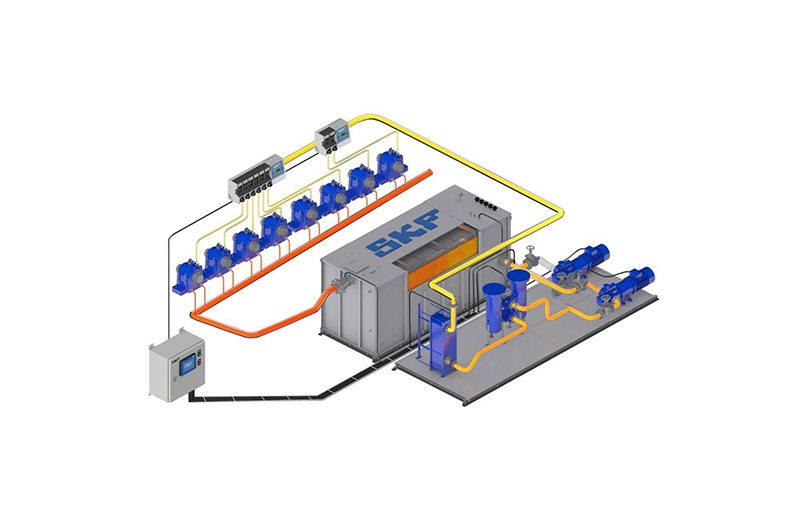

Single-Line Automatic Lubrication System

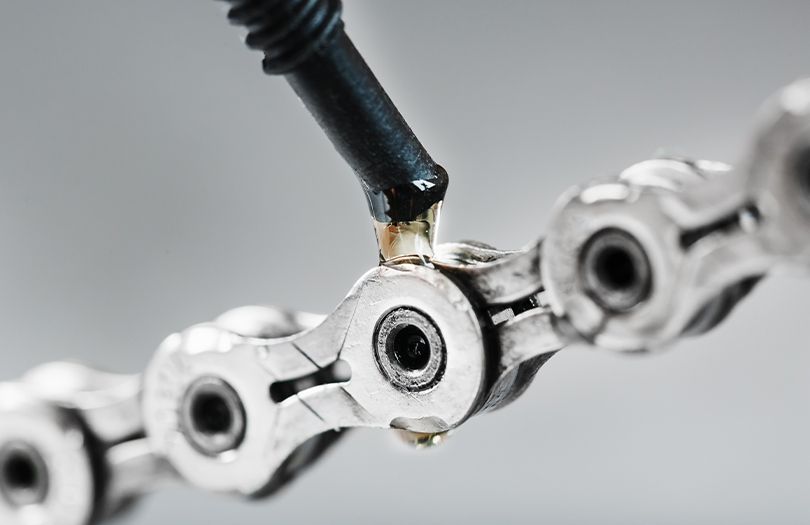

In Single-Line lubrication systems, the lubricant is delivered to a piston distributor/injector through a single feed line. Each injector outlet delivers lubricant to only onesingle lubrication point and can be easily adjusted to deliver precise amounts of lubricant. The set amount of lubricant is not affected by changes in fluid viscosity or backpressure(counterpressure) due to ambient conditions.. One of the most significant advantages of the syste is that, since the injectors operate independently of each other, a failure in one injector or a blockage in the feed line does not affect the rest of the system and it continues to operate. Single-line lubrication systems have a modular structure, so they can be easily revised when new lubrication points need to be added or removed.

Single-line systems can be used with liquid oils, liquid greases, and greases up to NLGI 2.

Benefits of Single-Line Automatic Lubrication System

- Easy to understand, install, and maintain

- Suitable for almost all lubricants

- Reliable • Easy system expansion

- The system continues to operate even if there is a problem in one of the lubrication points

- Can pump oil regularly over long distances and wide temperature range

Some Industries That Use Single-Line Automatic Lubrication Systems:

- Machine tools

- Automation

- Printing Machines

- Paper printing

- Construction machinery

- Cement industry

- Food industry

- Railway applications

- Steel industry