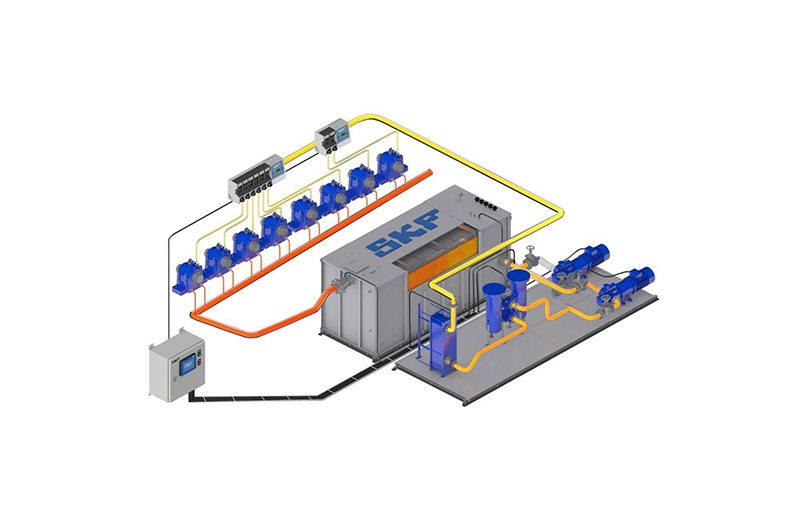

Grease Spraying Systems

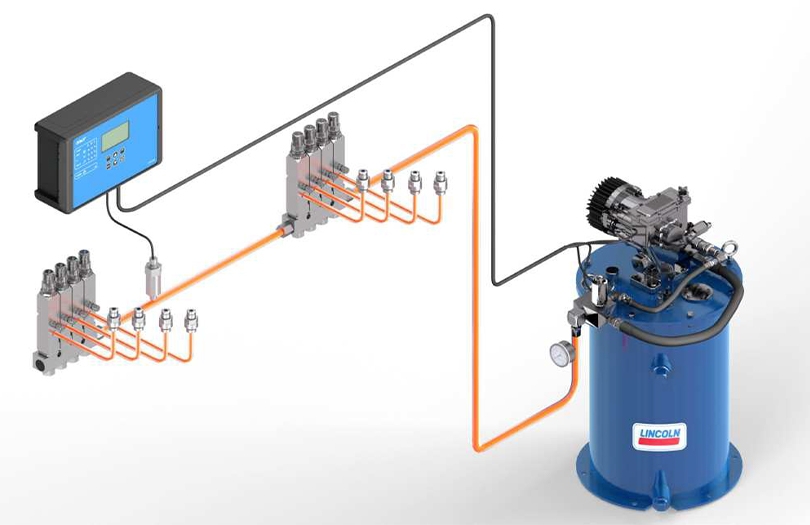

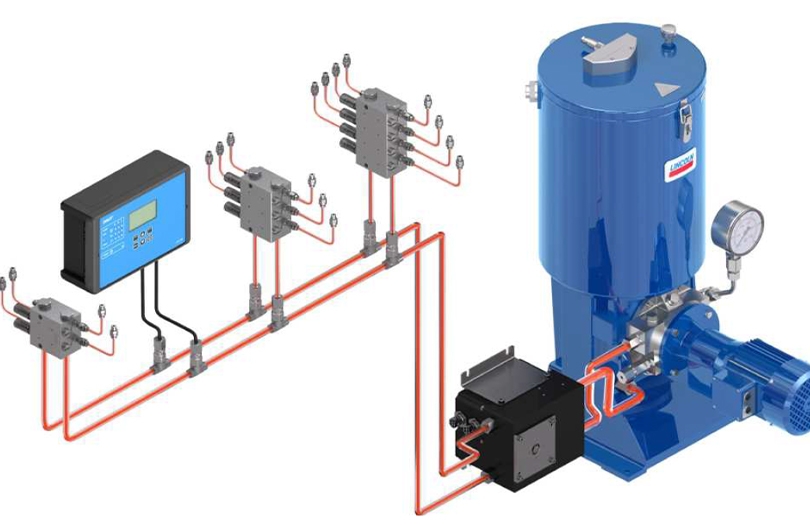

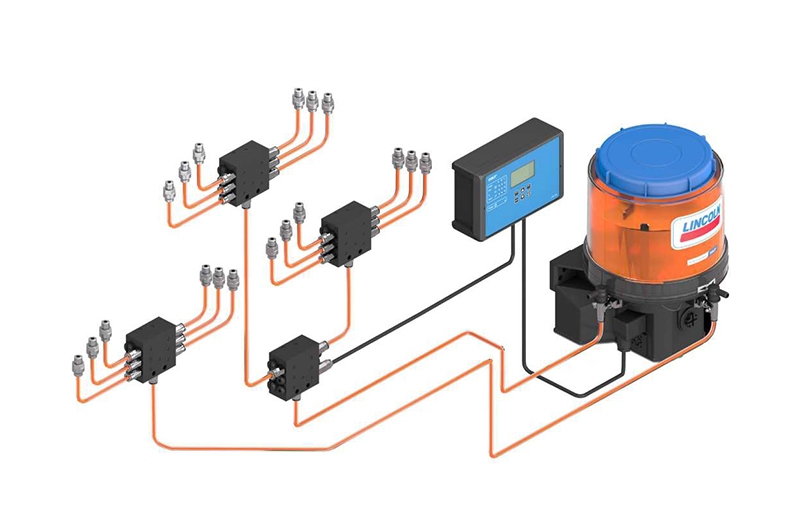

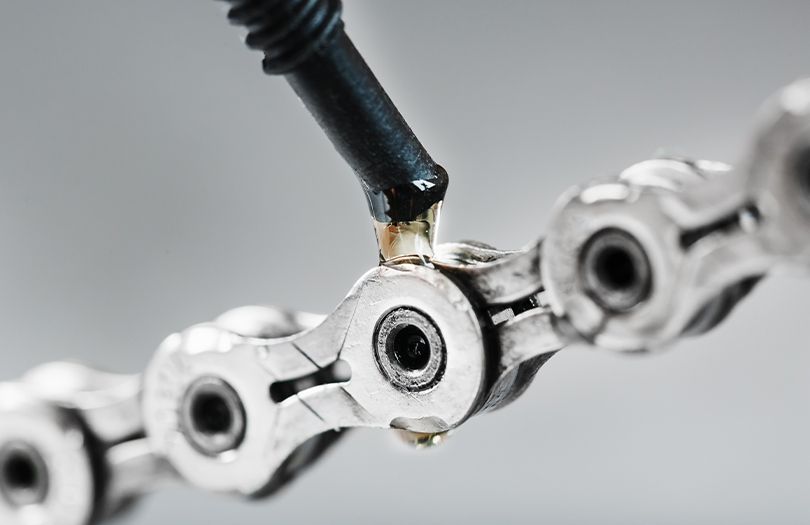

Lubrication is one of the important factors for the smooth operation of gear drives. The preferred spray lubrication system for gear lubrication, is designed as a fully automatic system to automatically spray the lubricant onto the gears.

The aim of the spray lubrication system is to create a film layer on the tooth flank, minimizing damage to the gear teeth. Spray lubrication systems are mostly used in large gear drives in cement plants, mining industry, fertilizer plants, ships and offshore platforms, cranes, steel production, waste incineration and composting plants.

With grease spraying system:

- Long-term sustainable reliability.

- Improved service life of gears.

- Lower maintenance and repair costs.

- Highly qualified equipment personnel can perform other tasks.

- Reduction of wear on drive pinions and surrounding gears.

- In the use of high viscosity lubricants, pulvarization and compressibility capabilities can be increased tanks to heating and isolation systems.

- The system and lubrication performance can be monitored by electrical control methods.

- The right amount of lubricant is delivered to the correct application surface at short intervals without wasting it.

- Systems are designed to suit changing ambient and lubricant conditions, ensuring that the lubricant is delivered to the spraying surface at the correct angle and distance.