Multi-line

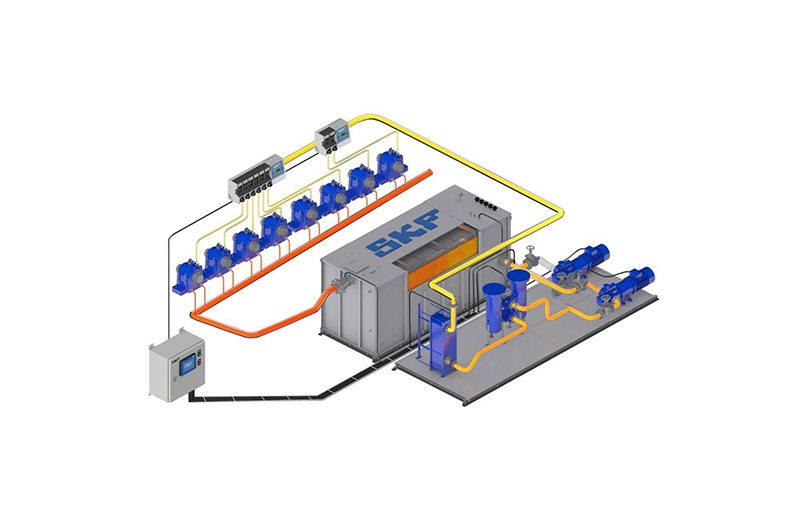

Multi-line Automatic Lubrication System

For demanding applications in nearly all industries

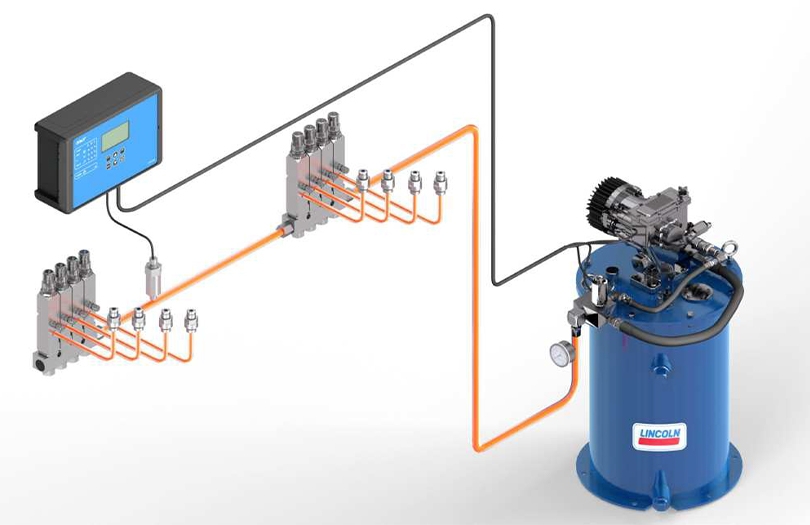

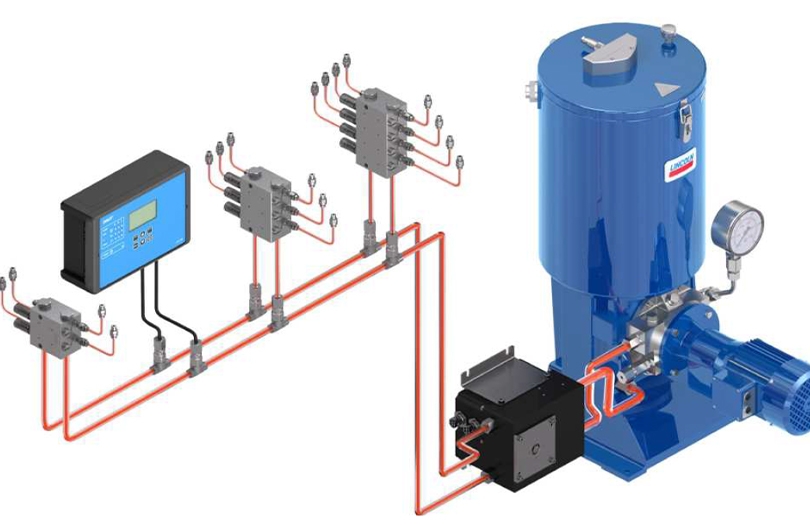

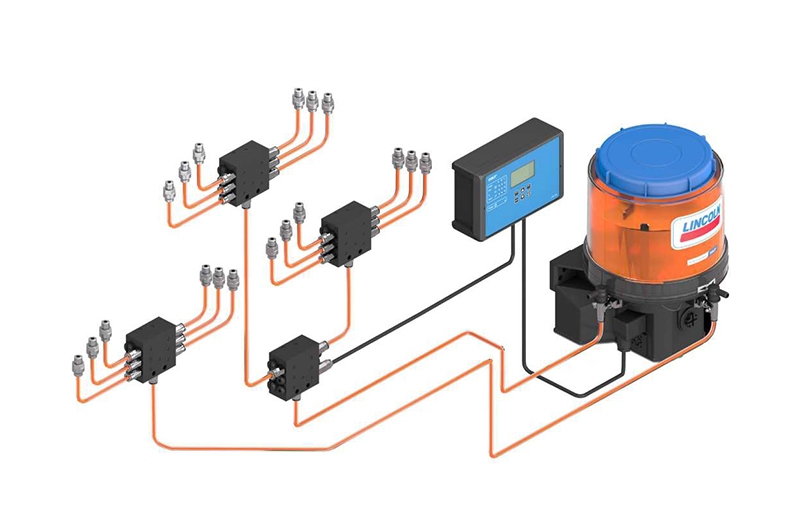

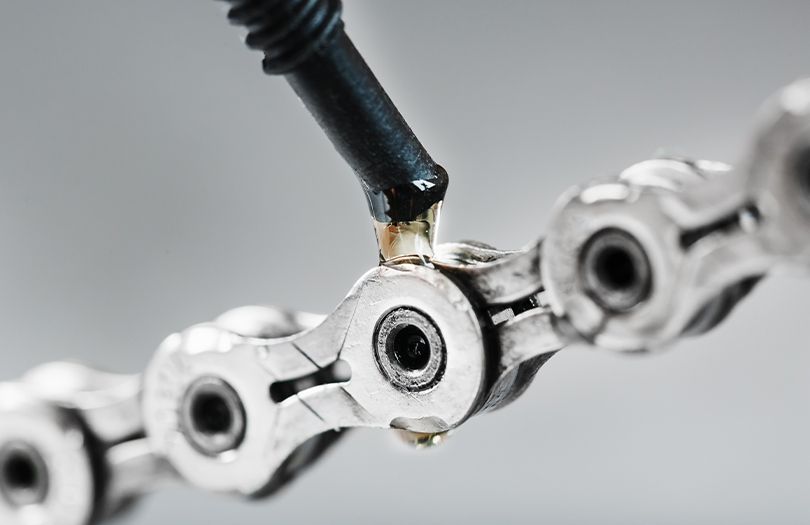

Multi-line pump units supply lubricant to lubrication points without extra metering devices. Thus, each lubrication point has its own pumping element The system design is simple, accurate, and most reliable. Multi-line pumps can be actuated mechanically, electrically, or hydraulically., Easily exchangable pumping elements are typically operated with an eccentric cam. By selecting pumping elements with different piston diameters and/or stroke settings, an individual lubrication volume setting per pump outlet is possible.

In multi-line lubrication systems:

- Pump element characteristics and reservoir capacity can be selected.

- Precise stroke volume can be set on the pump element.

- Wide viscosity range due to special designs and small piston clearance.

- Sturdy, durable pump series designed for 24/7 operation.

- ATEX explosion-proof versions are available.

- Additionally, they are compatible with level sensors coupled to the reservoir and progressive system distributors connected to the pump element output.

Some industries that use multi-line lubrication systems include:

- Crushers, cranes, and conveyors

- Construction and mining equipment • Tunneling machines

- Forging, bending, forming, and cutting presses

- Pumps and compressors • Rubber mixing machines

- Vacuum pumps, compressors (all types), and hypercompressor industry

- Compustion engines for valve and cylinder liner lubrication

- Important oil-total loss or very small oil circulation applications.

- Rubber mixing machines, critical plasticizing oil supply

- Water and sludge pumps

- Application areas requiring ATEX and API standards.