Minimum Quantity Lubrication

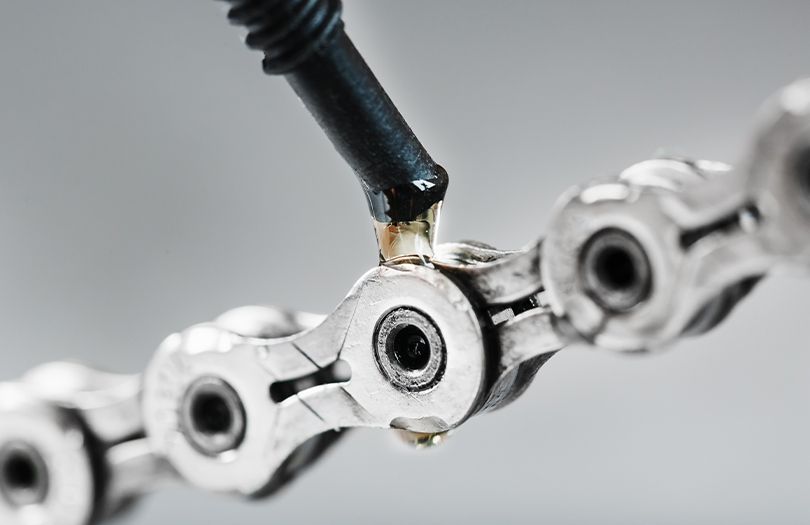

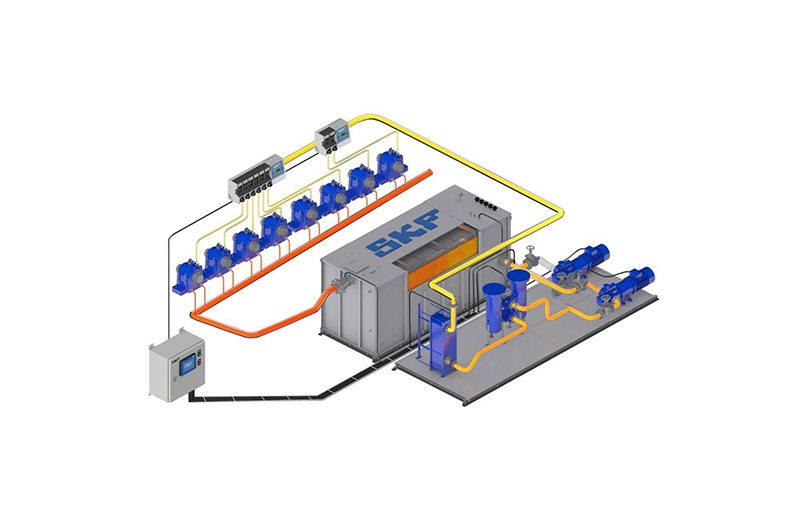

Machine operators can significantly reduce production costs by using minimum quantity lubrication (MQL) systems. These systems provide longer tool life and improved production quality through more precise surface machining.

MQL systems do not require cooling oil, which reduces the cost of oil, eliminates the need to adjust lubricant filters, and potential product losses.

Minimum quantity lubrication systems are used in applications such as milling, rolling, cutting, drilling, boring, and shaping.

Benefits of Minimum Quantity Lubrication Systems: • Extends the service life of the cutting tool • Increase productivity with higher cutting speed • Reduce maintenance costs • Enables better machining surface and quality • Reduce energy consumption and CO2 emissions