Dual-line

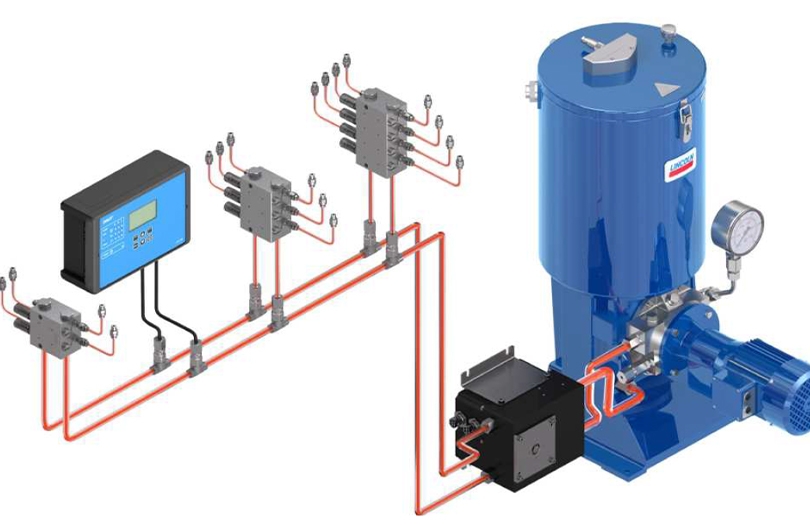

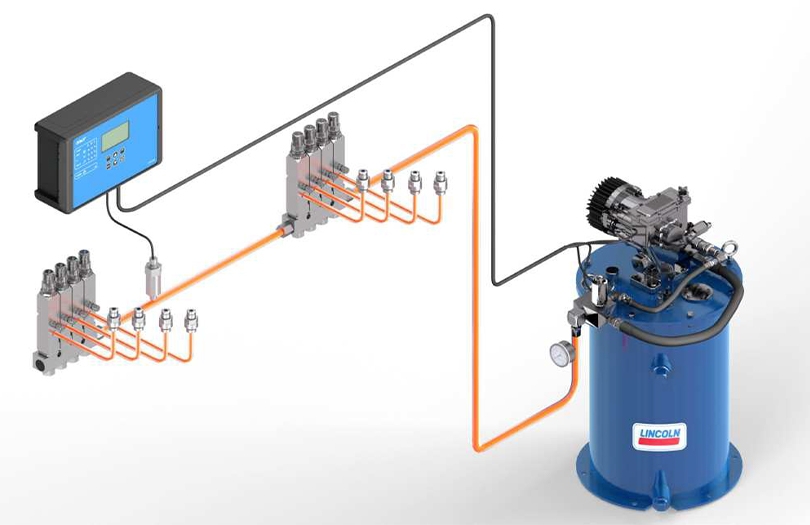

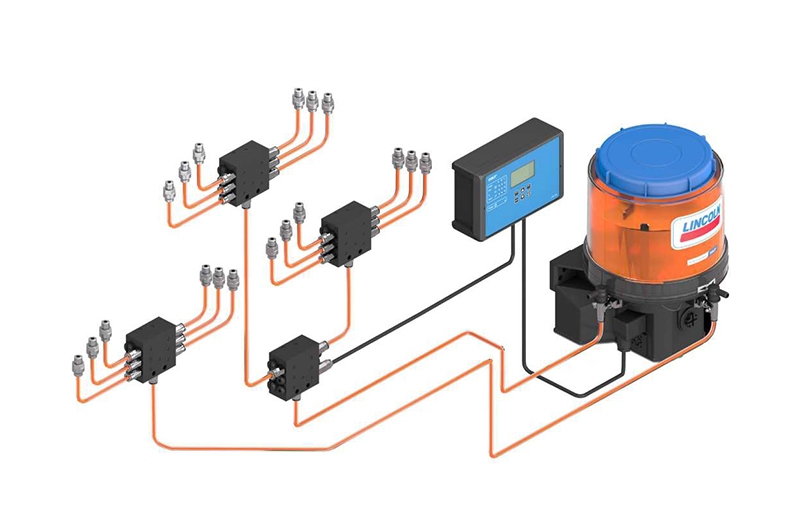

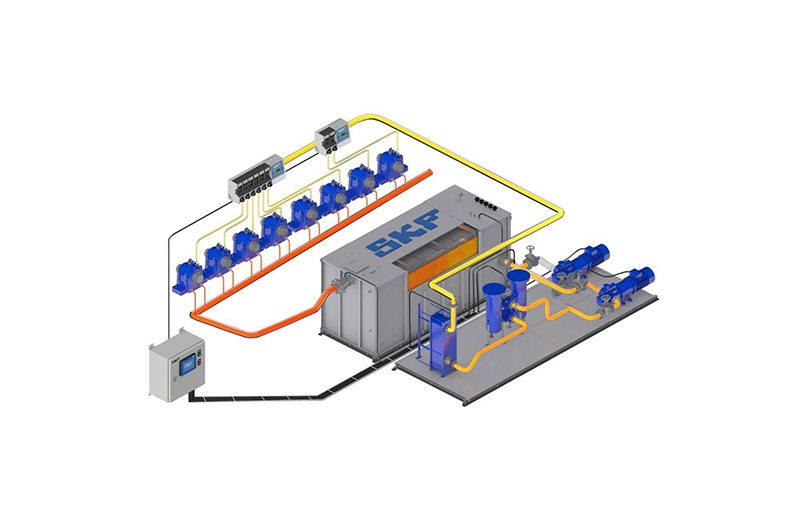

Dual-line Automatic Lubrication System

Dual-line systems distribute an adequate amount of lubricant precisely and proportionally to a large number of lubrication points over long distances. With a dual-line lubrication system, even if there is a blockage in one of the distributors, the system continues to operate and delivers oil to other lubrication points. The amount of lubricant dispensed from each dual outlet can be measured separately and monitored visually or electrically.

Dual-line systems have a flexible structure that can be expanded or contracted by adding or removing distributors. These systems are mostly used in heavy industries, metalworking facilities, pulp and paper mills, power plants, cement factories, mining, and mineral processing fields.

Dual-Line Lubrication System Catalog

Benefits of Dual-Line Automatic Centralized Lubrication System:

- Flexible, simple design, easy to expand or reduce • Reliable

- Precise and accurate lubrication for up to 2000 lubrication points at distances of up to 120m

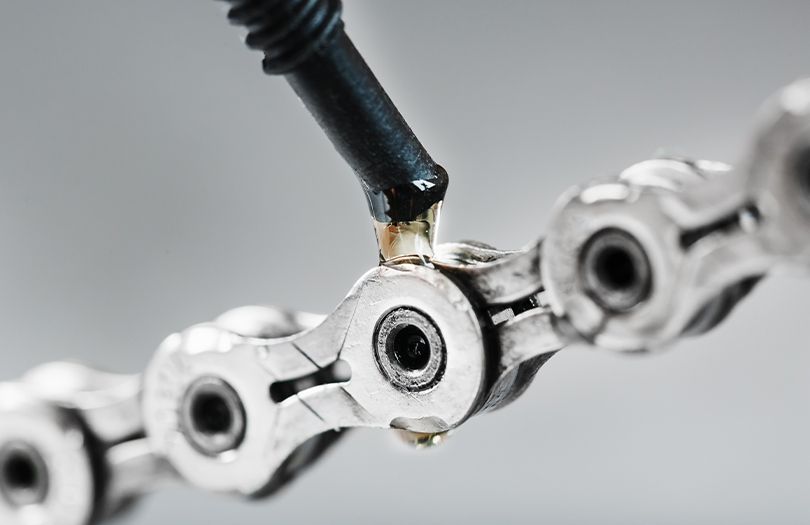

- Suitable for lubrication in applications that require a large amount of lubricant and independent adjustment

- Effective high-pressure lubrication at lubrication points under challenging conditions, such as low temperatures, dirt, wet or humid environments,