Railway Track Lubrication

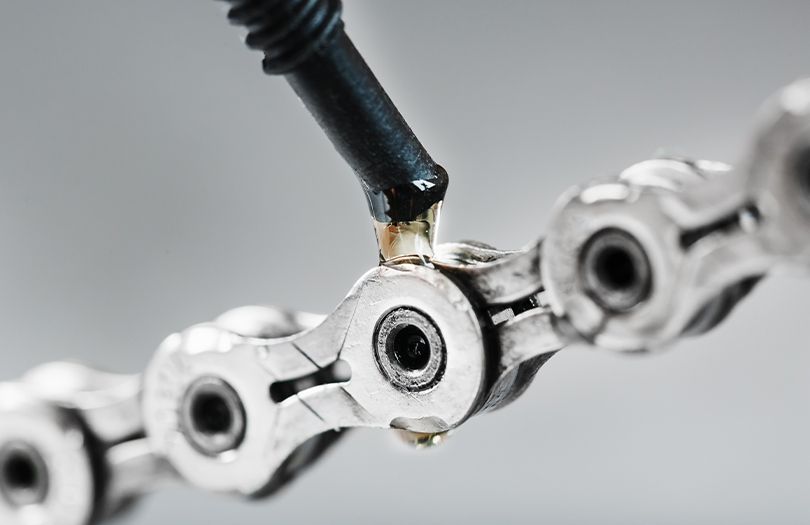

The biggest problem for rail system equipment is the friction force caused by the rail-wheel relationship, resulting high energy consumption, wear and noise problems. On-board and trackside fixed rail lubrication systems are used to minimize these problems..

In on-board lubrication systems, protecting the wheels from wear is generally the primary concern. The effect of lubricants used in on-board lubrication systems on rail wear is low due to their low viscosity class. The majority of on-board lubrication systems are controlled via a track curvature sensor, which is one of the system equipment. This ensures that the lubrication system is activated in curves where wear and noise are expected to occur. In cases where lubrication on curves is not sufficient, extra lubrication can also be applied depending on distance or time.

Fixed trackside rail lubrication systems are generally installed on sharp and narrow curves on tracks to minimize wear and noise. A low amount of lubricant is continuously supplied at certain intervals to create an appropriate lubrication film in the area. It is possible to use lubricants with high adhesive ability and containing high viscosity products and special additives in these systems.

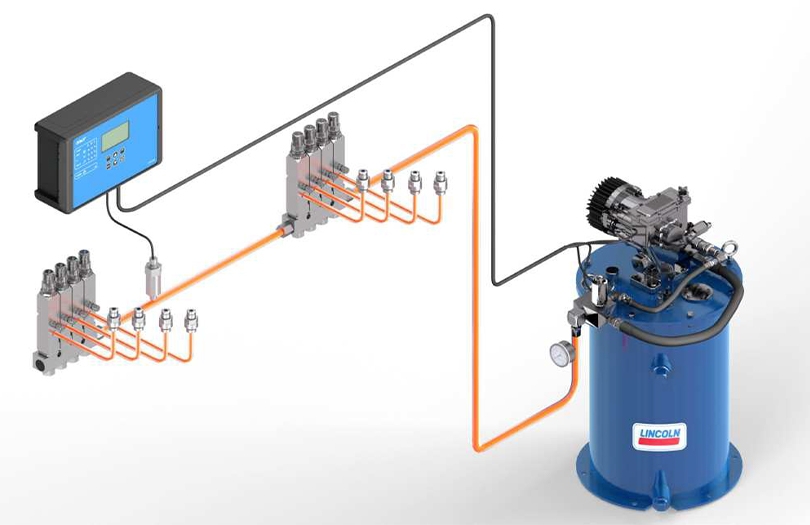

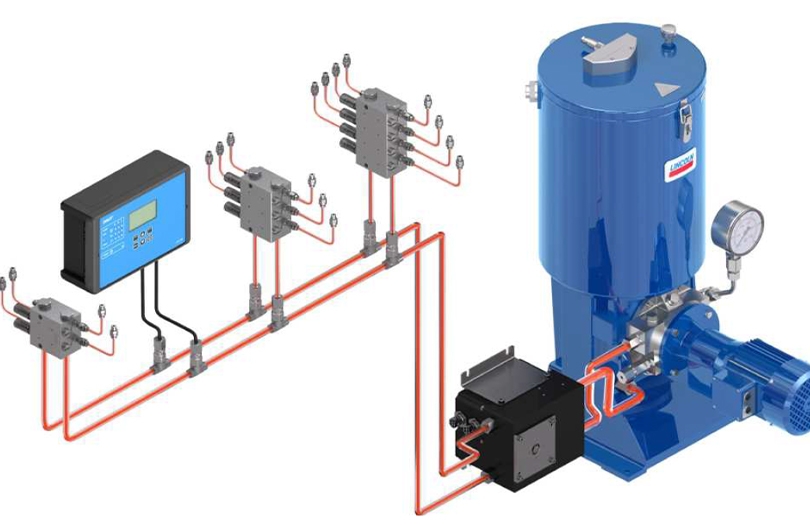

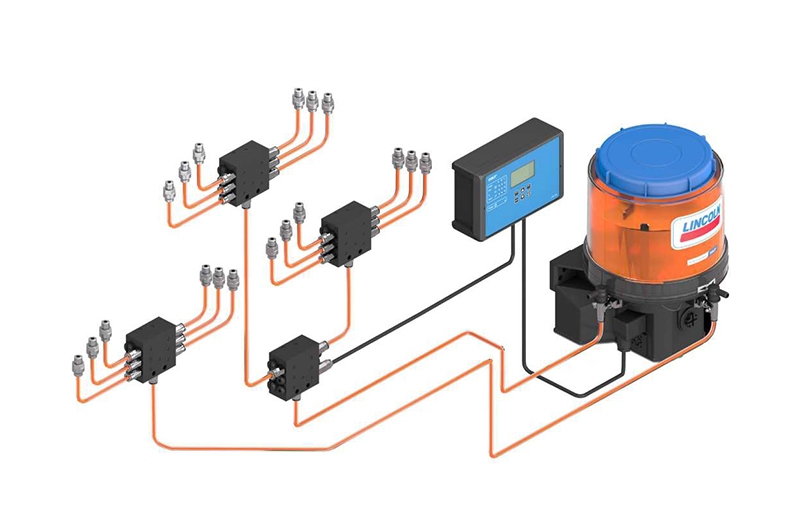

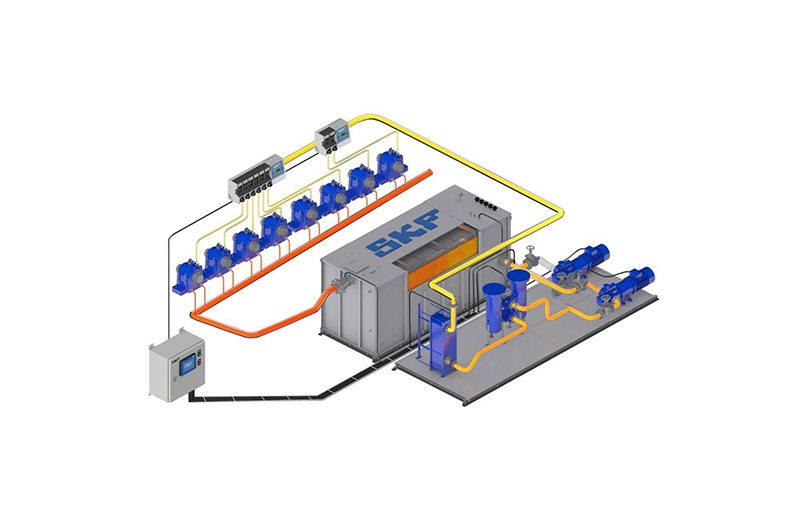

SKF/Lincoln lubrication systems, which have been serving the sector for many years and have references in many regions worldwide for similar applications, offer users the desired lubrication efficiency by using special production, high-pressure compatible system components, and optional auxiliary components to ensure continous lubrication even at low temperatures.

As Gresan, with our strong technical team and experience gained over the years, we have carried out many trackside rail lubrication and on-board lubrication system installations throughout Turkey, including tram, metro, and conventional lines, and we provide the necessary maintenance and control procedures at certain intervals to keep all of these systems running.